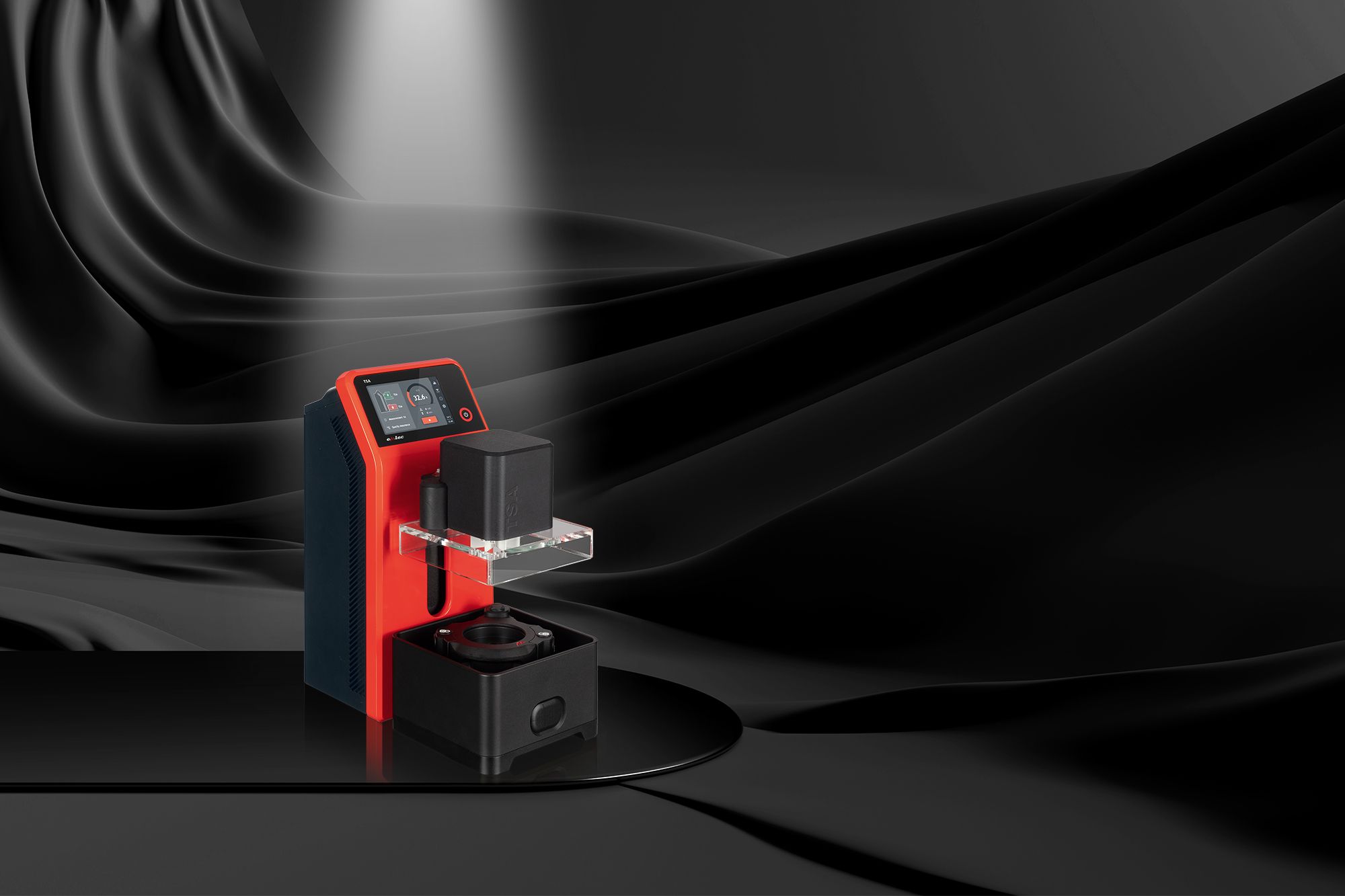

New TSA

An instrument to objectively measure haptic parameters with a high-quality design, additionally equipped with extending measuring functions and a new method for digitization.

FPO

The new emtec FPO Fiber Zeta Potential Analyzer Online uses the established measuring principle of the laboratory measuring device FPA touch! and delivers accurate results fast and reliable.

ACA

Measurement of the total filler content and the percentage distribution of the single components of paper and board, fast, accurate and non-destructive with the emtec ACA Ash Content Analyzer.

Emtec Electronic, located in Leipzig (Germany), develops and manufactures very specialized test devices mainly for the pulp and paper industry. Founded in 1995, emtec can look back to more than 25 very successful years. Within these 25 years several new developments have been launched successfully. Some of these inventions have become industrial standard over the years. Since 2014 emtec is also active in the nonwovens and textile industry with increasing success.

Today emtec has 34 employees. 13 different test devices are part of the current product portfolio, all developed by emtec (in some cases in cooperation with domestic and international partners). A sales network of 32 independent representatives is responsible for emtec’s activities in more than 80 countries worldwide.

Emtec test devices help the user to optimize production and converting processes as well as the product quality.

Innovative products, flexibility, customer-specific solutions and an outstanding service are our target and what made us successful during the last 25 years.

next Events

| Wed Jul 23, 2025 Texworld Textile Sourcing New York 2025 |

| Wed Aug 13, 2025 CIPTE 2025 |

| Mon Sep 29, 2025 Amsterdam Textile Show 2025 |

| Wed Oct 08, 2025 Japan TAPPI Meeting 2025 |

| Wed Oct 08, 2025 MIAC 2025 |

| Tue Oct 14, 2025 TITAS Taipei Innovative Textile Apllication Show 2025 |

| Thu Oct 23, 2025 APV Symposium of Paper Engineers 2025 |

| Tue Oct 28, 2025 ITMA Asia + CITME Singapore 2025 |

News

- Objective haptic testing for better decision-making – emtec at Texworld New York City

- 30 Years of Expertise: Testing device manufacturer emtec Electronic celebrates its anniversary at the Zellcheming-Expo in Wiesbaden

- emtec Electronic in Apeldoorn: Innovative Measuring Devices for Sustainable Process Optimization and Quality Improvement

- Paper & Biorefinery: Emtec´s Innovations in Graz

- Minimizing Environmental Impact and Controlling Costs with emtec Electronic´s Testing Solutions at Paper & Tissue Expo Istanbul

- emtec`s Industry Networking for the Future of Textile Measurement: Collaboration with Harrie Schoots

Most Read

- The emtec ACA Ash Content Analyzer provides valuable information about the total mineral filler content and the percentage content of the individual filler components in paper and board.

- Emtec TSA Tissue Softness Analyzer – new features of a well-known device

- The characterization of the surface pore structure helps to solve issues with the gluability

- Objective measurement of softness, roughness, stiffness and the recovery parameters elongation, hysteresis and plasticity

- Emtec test devices allow a detailed evaluation of paper and board characteristics

- Objective measurement of softness – now even possible with hand sheets

- New measuring method to evaluate the Hand Feel (HF) of Fiber Resources

- New TAPPI TIP Technical Information Paper 0808-07 (2021) Explores Performance of emtec Tissue Softness Analyzer

- The best practice for process and product optimization