The emtec ACA Ash Content Analyzer provides valuable information about the total mineral filler content and the percentage content of the individual filler components in paper and board.

With the Ash Content Analyzer (ACA), emtec Electronic aims to overcome the disadvantages of the traditional combustion method. The innovative lab instrument replaces combustion with x-ray technology, enabling the non-destructive measurement of individual mineral fillers in paper and board, such as Calcium Carbonate, Kaolin/ Talcum, Titanium Dioxide or Barium White shown as combined or separate results. Time consuming test procedures are no longer necessary and the data are available for process optimization in less than one minute.

High accuracy due to less dependency on environmental and human influences

„Independent of the user or the state of the sample, the instrument always measures the correct amount of the used fillers and fines," says Giselher Grüner, General Manager of emtec Electronic GmbH. In comparison to the combustion, the results depend less on the moisture of the sample and the results are available within seconds, which allows an intermediate intervention in the process in case of issues. Besides this, the new method is much more accurate and reliable – the margin of error is less than one percent. In addition to its simple handling, the ACA device is easy to transport, needs less space in the laboratory and is quickly installed.

Easy to understand and handle, precise data with little effort and cost

As mentioned earlier, the new monitoring process enables an immediate reaction to process changes and continuous optimization of the paper and board production. Process variability can be significantly reduced in the future and the production of e.g. decorative paper, copy or printing paper or even banknote paper will become more efficient.

Other possible applications come from historical research. Especially for historical documents, the combustion method cannot be applied. With the x-ray technology from emtec, data such as the age of the paper and its origin can now be analyzed on the basis of the mineral fillers - without burning the available material.

The combustion method can be a thing of the past

With the traditional measuring method it takes hours or even days to get the total filler content of minerals. In addition to the time needed for the tests, a lot of energy is also used to get the necessary information, which is also limited. With the help of the combustion method, only certain fillers can be detected, which only provide an approximate picture of the paper´s ingrediants. With the emtec ACA however, this has changed.

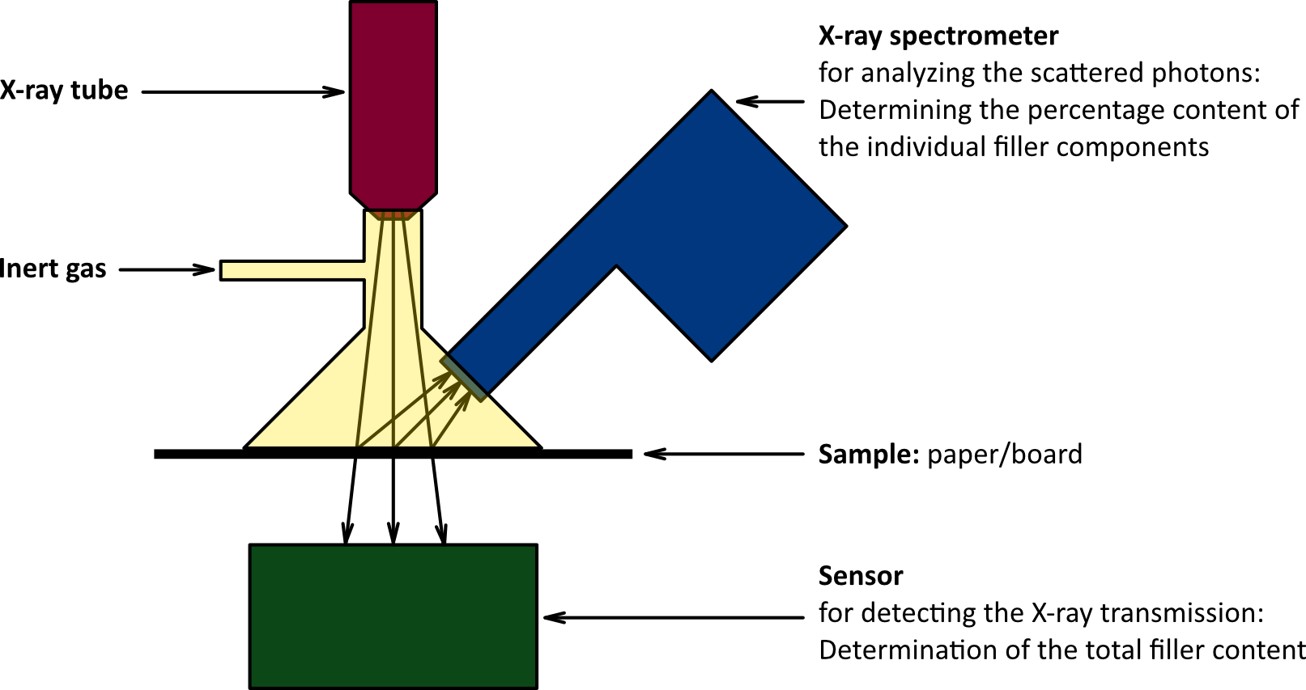

The measuring method of the ACA is based on a combination of x-ray fluorescence analysis and the transmission method. First, the captured x-ray fluorescence spectra are qualitatively evaluated, and afterwards, they are quantitatively determined concerning the concentration of the detected filler components. The signal peaks are converted using complex mathematical functions (algorithms) in the corresponding concentrations.

Higher quality sensitivity of the consumer, environmental requirements, a much more complex industry

Processes are getting more and more complex. Paper and board producers face more and more rules for efficient environmental protection. Consumers are getting more and more quality sensitive, but also expect to get the product for a reasonable prince All these factors force paper and board makers, as well as converters, to use resources and additives as efficient as possible in order to keep the cost and the environmental impact of the production as low as possible. The efficient use of resources also includes fillers and fines that are used to influence the quality of the paper or board in a certain way. The traditional combustion method is only able to provide a rough picture of what amount of fillers and fines is in the paper. The emtec ACA, on the other hand, is able to detect the total filler content as well as the percentage content of the individual filler components in the paper and board and thus helps to optmize the process as well as the product quality.

The next chance to experience this fascinating new test device is the MIAC – International Exhibition of the Paper Industry in Lucca, Italy, from October 9-11 2019.