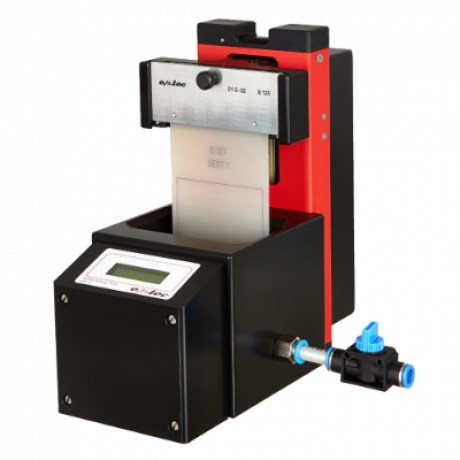

PDA.C 02 MST - Module Standard

The emtec PDA.C02 Penetration Dynamics Analyzer (plus Module Standard, MST) helps to predict the gluability, printability and coating-ability of paper and board by measuring the converting-relevant parameters surface sizing (surface hydrophobia) and surface pore structure.

Product description

To make sure that the necessary product quality can be reached, specifications are agreed between paper maker and converter. These specifications are bases on standard test devices, such as Cobb or Gurley. But often it happens that although the quality of the base paper or board is within the agreed specifications, issues with the gluability, printability or coating-ability occur during the converting.

Since gluability, printability and coating-ability mainly depend on surface sizing and surface porosity, information about these two parameters are very important. But the standard test devices are not able to measure them. In comparison to this, the emtec PDA is able to measure these two very important surface parameters within the time that is relevant for the converting process and by this helps to ensure a well-running converting process and the right product quality.

Users

Application areas

Results

t95 value

surface porosity

MAX value

surface sizing/hydrophobia