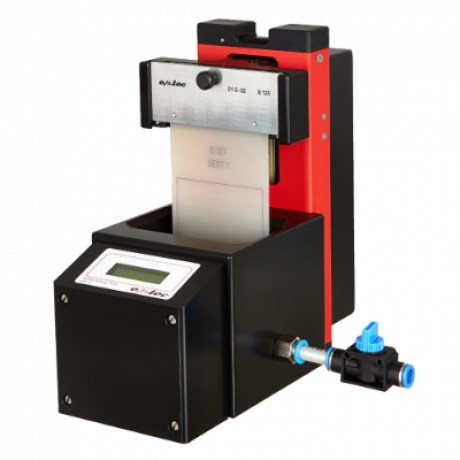

PDA.C 02 MSC - Module Standard Coating

With the emtec PDA.C02 Penetration Dynamics Analyzer and the Module Standard Coating (MSC), which has especially been designed for the use of coating color as test liquid, the interaction between coating color and base paper, the surface sizing and surface porosity as well as the coating quality can be determined.

Product description

The PDA.C 02 - Module MSC Standard Coating helps to detect changes in base papers, coating colors, and coated papers, which are not detected by standard test devices, but which can lead issues with the coating-ability during the converting process.

The contact between coating color and base coating paper happens under high shear and pressure pulse, leading to a good simulation of the coating machine applicator.

Pilot coater and machine trials indicate the effects of coating color and base paper variations. The PDA.C 02 provides a tool to explore the causes.

Users

Application areas

Results

Max value

surface sizing/hydrophobia

t95 value

surface porosity